MCT5000 5 Axis CNC Tool

Cutter Grinder

Machine Control Technology's MCT5000 5 axis CNC Universal Tool & Cutter Grinders is the most flexible and cost effective CNC machine for standard and form tool manufacturing, regrinding, and parts grinding industries. The MCT5000 CNC Tool & Cutter Grinder allows you to do spiral flute, straight flute, primary & secondary relieves, end & radius, counter-sink relief and step O.D. grinding from a blank, or regrinding tool with built-in software. The machine is capable of producing or regrinding a finished tool in one continuing operations. And the G code programming is also provided for the flexibilities of your custom tool grinding.

|

|

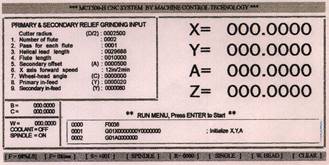

MCT5000 Control Display Novatech,

Inc. |

|

MCT5000 5-axis CNC Grinder |

|

Complete tool grinding capacity from 3/32” to 1-1/8". One inch/minute for solid carbide in one pass flute grinding. Fully automatic with 3D probing. Custom auto-loader capabilities

The MCT5000 CNC Tool & Cutter Grinder is the most

affordable 5 axis advanced CNC tool & cutter grinder. The cost just a

little over one year of an experienced tool grinder’s salary, but will produce

three to four times more than an experienced tool grinder with a manual

machine!

- Easy to use, just fill in tool and wheel information and you are ready to go

- Optional 3D automatic probe

- Standard 5C air collet closer

- Built-in 30 gallons 1 /2 hp coolant system

- Built-in complete tool grinding macro-programs

- 0.0001" control resolution

- Optional MCT production auto-loader

- 5 hp variable speed grinding spindle

- G code on/off line programming form-tool grinding

Machine System

The machine body of the MCT5000 Tool & Cutter Grinder is

a fully enclosed grinding machine. It is built on a strong steel base with a

6" thick granite on top for dampening. All X, Y, Z axis are built with

precision linear guide ways and ball-screws for providing smoother control and

long lasting machine life. The machine has two rotary axes. The C axis is

mounted on top of the Y axis and carries the X, U, V, and A axis. The C axis is

capable of swiveling within 230 deg. around the rotary center for radius, ball

nose and left/right hand rotary or flat tool grinding without sacrificing tool

grinding length. The machine is also equipped with 3/4 horse power coolant

pump, a 30 gallons coolant tank and a filter system.

Spindle Power

The MCT5000 series 5 axis CNC Tool & Cutter grinder

provides a standard variable speed 5 hp spindle motor. The spindle is belt

driven for easy maintenance.

Air collet closer

Standard 5C air collet closer for quick and easy tool

changing by hand. This capability improves operator efficiency while running

the machine.

Software

The Machine Control Technology's MCT5000 series 5 axis CNC Tool & Cutter

Grinders have built-in macro-programs for end mil, reamer; counter-sink

step-drill, step O.D. and engraving tools with spiral or straight flute

grinding, Just fill in the tool grinding information, no expensive grinding

software are needed to run the machine. Custom built-in special programs are

also our advantage over the other expansive CNC tool grinders, only Machine

Control Technology is flexible enough to do that. Besides all these built-in

software, the MCT5000 Tool & Cutter grinders are also allowing you to write

your own programs with G-code in edit mode.

Automatic Probing

The optional automatic probe is provided for faster, easier

and more accurate checking on helical lead length, flute length and flute

position for regrinding.

Lead Length Probing

The automatic lead length probing capability is an optional feature which allows setting the touch probe to touch two points on the tool flute edge. The machine will automatically calculate the lead length and place the lead length value in the auto-programming menu as one of the menu input data.

Programmable Reload Pointer

The programmable reload pointer is also a standard feature

designed as a 3 dimensional stop for locating the reloading tool to the

starting position without the automatic probe. When the machine finishes

grinding the current tool moved to the packing position, then you unload and

load another tool, press the "Enter” key, a reload pointer will move to

the reload position to tell you where you should lineup and lock your reloaded

tool. Then press "Enter" to start another cycle.

Autoloader Capability

The MCT integrated optional autoloader is a patent pending

advanced auto-loader that is capable of loading different size and shapes of

tools or parts, for the MCT5000 Tool & Cutter Grinder. And it can also be

designed for custom applications and requirement.

CNC Controller

The MCT5000s CNC controller is perhaps the most compact, dedicated and yet flexible CNC controller for tool grinding machines you can find. It is specifically designed for the tool & cutter grinding machines by Machine Control Technology with lots of experience in electronic controller design. The controller is easy to use and is a reliable controller, with machine control technology's free phone technical support, you can count on it.

|

Specification |

|

X-axis |

Y-axis |

Z-axis |

A-axis |

C-axis |

|

Travel |

|

11” |

11” |

11” |

index/free |

230° |

|

Servo resolution |

|

0.000025” |

0.000025” |

0.000025” |

0.000025/rev. |

0.001° |

Work-head RPM: 400 RPM Maximum

Spindle power: 5HP, 220V AC 3 phase

Spindle RPM: 3,500, variable control up to 10.000 RPM

Controller power: 110V AC 1,200W

Servo motors: DC servo motors

Size: 72" L, 60" W. 78" H

Weight: approx 4000 lbs

All specifications and prices are subject to

change without notice.